From Scan to Dressform

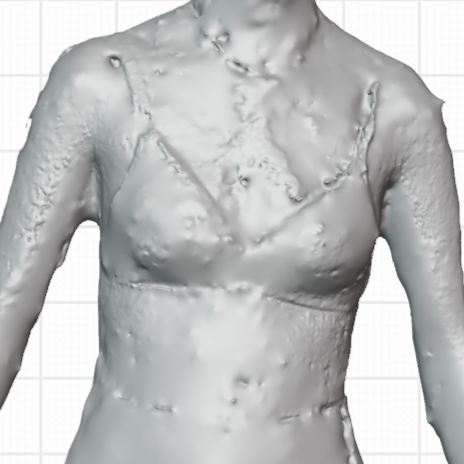

Scan Cleanup

We use special design software to clean up the scan—removing extra bits, smoothing the surface, fixing holes, and getting it ready for the next steps. It takes a lot of behind-the-scenes work to turn the scan into something we can build from.

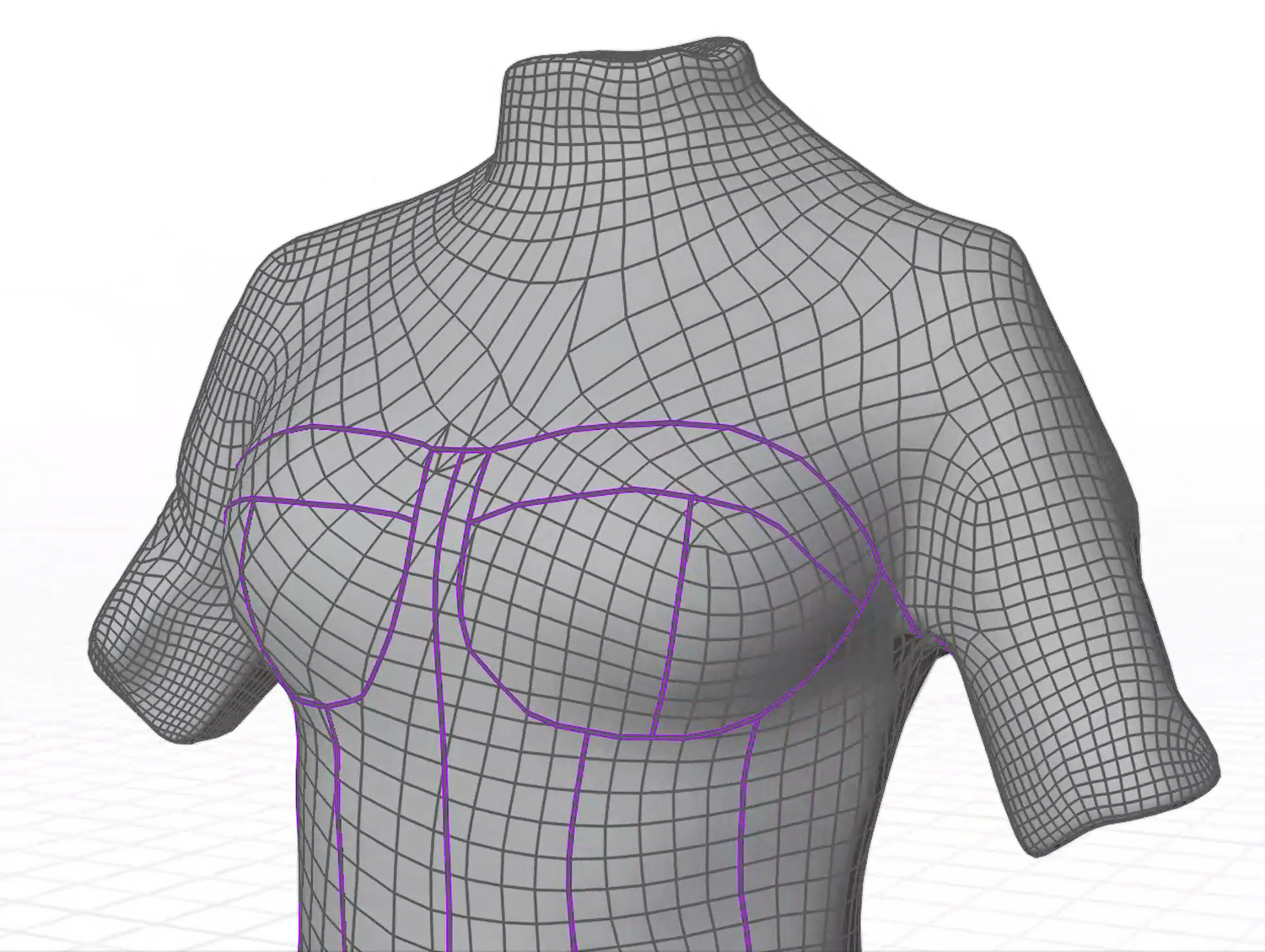

Making the Pattern

Once the scan is cleaned up, we draw on "seams"—like doodling where you would peel an orange. Then we "unwrap" it, turning the 3D shape into flat pieces, just like peeling the orange into sections. Those pieces become a pattern for us to use.

Building the Support Structure

To keep the dressform secure on the stand, several support structures are added. The base is made from solid wood with an inner pipe structure to prevent leaning. The neck and armholes are reinforced with cardboard to maintain their flat, structured shape.

Putting it all together

The fabric is cut, sewn together and attached to the wooden base. The dressform is then stuffed with Polyfil and the cardboard pieces are used to seal the dressform. Lastly, the dressform is steamed and molded to harden the dressform into its final shape.